FieryCut 2.1.5 Crack With Activator

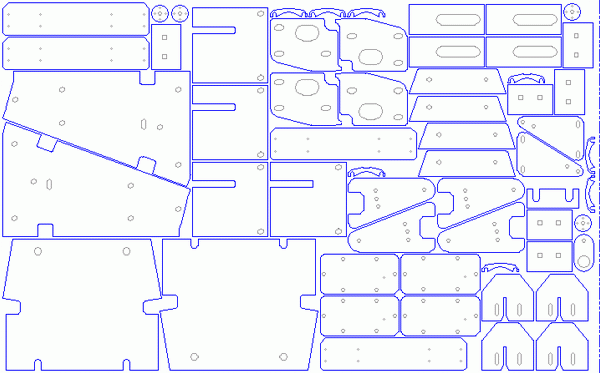

FieryCut is a powerful application designed to create nesting of parts on sheet materials and create CNC programs for profile cutting machines. The FieryCut automatic nesting software reduces the waste of sheet material at manufacturing parts of any profile from sheet metal (steel), wood, glass, fabric, leather and any other sheet material.

The FieryCut automatic nesting software consists of three modules:

Download FieryCut Crack

| Software developer |

ExactCAM

|

| Grade |

4.5

1090

4.5

|

| Downloads count | 9062 |

| File size | < 1 MB |

| Systems | Windows 2K, Windows XP, Windows Vista, Windows Vista 64 bit |

· Creation of parts geometry (Geometry);

· Accommodation of parts on a sheet metal (Nesting);

· Creation of the CNC program for profile cutting machines (Cutting).

Module of work with geometry (Geometry):

· Automatic creation of parts contours using the drawn or imported geometry.

· Support of parts and stocks having rectangular and complex geometry.

· Nesting of contours is not limited.

· Used elements for construction of profiles - line, arc, circle, polyline.

Test and automatic editing of errors in geometry (imposing of contours, breaks of contours).

· Test of profiles on intersecting.

· Test of profiles on breaks.

· Change type Lead-in / Lead-out generation – Yes/No.

· Change type of a profile – In/Out.

· Calculation of the area of a surface and weight of parts.

· Report on contours and operating ratio of sheet metal.

Module of parts nesting on a sheet material (Nesting):

· Automatic nesting of parts on stocks of any profile. It allows to use scraps of a sheet metal of any profile.

· Interactive / manual nesting. Auto nesting + Manual nesting (moving, addition, removal of parts).

· Multiple stocks in a single job.

· Using of groups of parts.

· Using of holes for automatic nesting of parts (Only the Advanced method).

· Restriction on allowable rotation angle of parts. The control of an allowable rotation angle of parts.

· Priority of sequence of parts placing can be established for each a part.

· Two methods of parts nesting:

· Rectangular nesting. This method allows placing parts having the rectangular and non-rectangular form. To have possibility of automatic nesting of parts in holes of other parts, it is necessary to use Advanced Nesting.

· Advanced nesting (Shape nesting). This method is used for nesting of parts of any profile. The FieryCut Serial nesting software automatically places parts in holes of other parts.

Nesting parts on stock using displacement between parts and stock.

· Visualization of nesting.

· Report on results of nesting on each sheet.

Module of creation of CNC programs (Cutting):

· Automatic toolpath generation.

· Toolpath optimization.

· Nesting of parts in other parts it is not limited.

· Manual toolpath generation.

· Editing of the commands of cutting (the insert, removal, redefinition, change of sequence).

· CNC code generation (CNC program) for profile cutting machines.

· Calculation of time of cutting, and also total length of working and fast moving (for calculation of power inputs at cutting).

· Cut simulation.

· Generator of postprocessors. Using it you will easily and quickly create a new postprocessor or will edit the existing one. If necessary, our specialists will adjust postprocessors for your machine tools free of charge.