Cheewoo Pipe CAM 2.4.3001.1002 Serial Key Full Version

Complex cutting machines can nowadays be used to create 3D representations of nearly anything, but also for industrial parts and day-to-day objects. The machine cuts according to a set of instructions, which can be created with the help of specialized applications like Cheewoo Pipe CAM, this one dedicated to pipe cutting profiles.

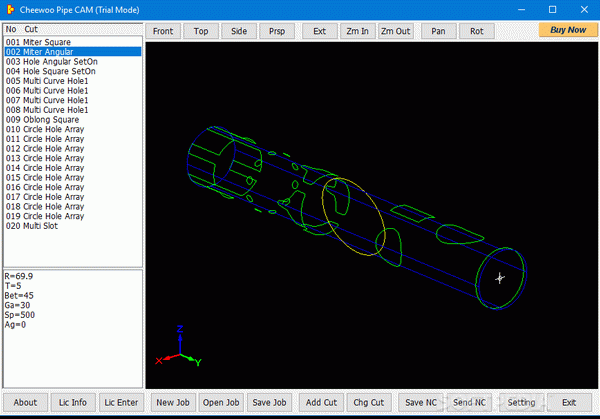

The application takes little time to install and you can take it for a spin right afterwards. It stores its features in a clean interface, with most of the space representing the canvas. A side panel lets you view and manage elements, as well as related details on selection. The canvas is interactive, allowing you to rotate and zoom on the object.

Download Cheewoo Pipe CAM Crack

| Software developer |

CHEEWOO Engineering

|

| Grade |

3.1

860

3.1

|

| Downloads count | 6556 |

| File size | < 1 MB |

| Systems | Windows All |

You can either start from scratch or load an existing project. Creating a profile is done by adding cut sections in your work. The application comes with an impressive variety of items like pipe branch, pipe trunk, as well as complex shapes. These are also fitted with visual representations of the object and its plan, and you need to appropriately fill in position and size values.

It’s a good idea to pay a visit to the settings panel first to dictate cutting, machine, and code settings. These refer to lead-in/lead-out length settings, undercut and overcut, feed speed, torch pause time, whether or not to return to start position when done, control axis, pipe drive type, cutting device, and more.

One of the core features of the application is to help you build an accurate plan and generate the corresponding NC code which is required by the CNC machine. On the bright side of things, you can connect the program directly to a machine via RS232C data sending from the settings panel. If connection is established, the code can be pushed directly for processing.

All things considered, we can state that Cheewoo Pipe CAM Serial is a neat application which allows you to design complex pipe cutting profiles, generate the necessary NC code, or even directly start cutting via a connected CNC machine.