Cheewoo Nest 2D 2.5.1010.1029 Crack With Serial Number 2025

Specialized machines are nowadays used to cut out various pieces from different materials, and the command for these cut-outs are sent from a computer. In order to maximize space efficiency and minimize waste, Cheewoo Nest 2D comes as an application which can help you make the most out of a cutting plan.

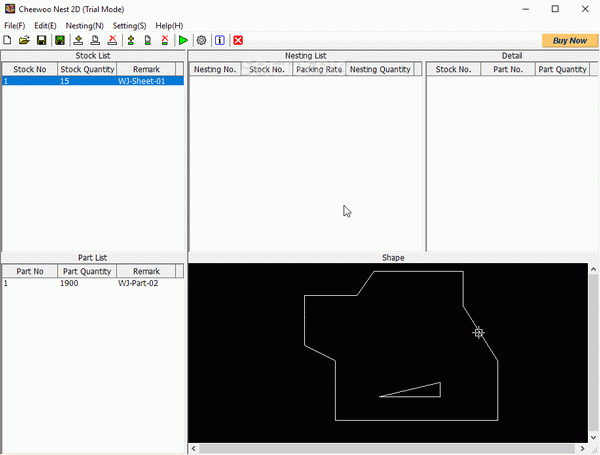

One first note is that the application requires .NET Framework to function, but it’s usually delivered as a default feature in modern Windows iterations, so there’s a high chance it’s already on your computer. As far as the interface is concerned, elements are neatly integrated in a simplistic design, but keeping this intuitive.

Download Cheewoo Nest 2D Crack

| Software developer |

CHEEWOO Engineering

|

| Grade |

4.0

831

4.0

|

| Downloads count | 6191 |

| File size | < 1 MB |

| Systems | Windows All |

The application requires a couple of things from you, such as a sheet and part. These can be easily added through dedicated menus which let you specify the quantity, stock remark, and possibility to use a DXF file as input so the application can calculate the best space distribution in your cutting plan.

Once a new job is created and all necessary files loaded, data is displayed in quite an intuitive design. Individual panels show lists of stock, parts, nesting, and details. More than that, the shape is also shown, with necessary adjustments included once nesting is done.

Before you start the nesting operation, which is automated, there’s the possibility to configure algorithm behavior to get things just right. The settings menu lets you specify packing interval, packing gravity and strength values, as well as minimum gap between parts.

As mentioned, nesting calculus is automatically performed at the press of a button. Unfortunately, the application is not a method of generating the necessary G-code, but rather to generate an efficient cutting plan. The result can be saved as DXF for further processing with advanced apps, or as BMP.

All in all, Cheewoo Nest 2D Serial can help you make the most out of cutting plans by efficiently arranging parts on a canvas. Calculus is performed to use as most space as possible and minimizing waste material.